BIS Scheme-X Certification

The Bureau of Indian Standards (BIS) has introduced the Scheme X Certification, a regulatory framework that ensures the safety, quality, and conformity of machinery and electrical equipment in India. Officially launched on 16th March 2022 under the BIS Conformity Assessment Regulations, 2018, Scheme X is specifically designed for industries that manufacture and supply products such as electrical motors, transformers, power generators, pumps, compressors, welding machines, elevators, escalators, cranes, and conveyors.

- Overview

- Scheme X Ceritification

- Scope of BIS Scheme-X Certification

- Omnibus Technical Regulation (OTR)

- BIS Certification for Machinery and Electrical Equipment Safety (Omnibus Technical Regulation)

- Guidelines for Using the BIS Standard Mark

- BIS Scheme X Certification

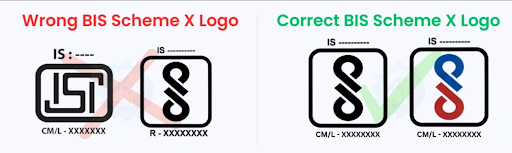

- Guidelines for Using the BIS Standard Mark

- Key Differences Between Scheme-I & Scheme-X

- Category Of Products Listed Under Scheme-X

- Safety Standards Under BIS Scheme-X

- Compliance with Indian Standards under Scheme-X

- Procedure

- Documentation

- Steps for Getting BIS Certification Under Scheme-X

- Additional Points

- BIS Scheme-X Certification Fee

- Conclusion

- Frequently Asked Question (FAQ)

BIS Scheme-X Certification - Overview

Scheme X was introduced by the Bureau of Indian Standards (BIS) on March 16, 2002. The main purpose of introducing this scheme was to make sure that Indian and Foreign manufacturers get the required certification for their machinery, machine tools and assemblies before they can sell their products in India. This helps maintain safety and quality in the market.

Under this scheme, BIS provides a license or Certificate of Conformity (CoC) for products like low-voltage switchgear, control gear, electrical equipment, and machinery. Products that are certified can carry a BIS mark.

By following Scheme X, manufacturers can prove that their products follow the Indian standards and government regulations.This increases customer trust, ensures product safety, and improves the credibility of both domestic and international manufacturers selling in India.

Scheme X Certification

Scheme X is a certification program to certify the products, launched by the Bureau of Indian Standards (BIS) under the Conformity Assessment Regulations, 2018 and later updated in 2022 through an amendment. The scheme is designed to bring Indian safety standards in line with international practices. It covers machinery and electrical equipment that are either made in India or imported into the country. Through this scheme, the products are tested and certified to make sure that they adhere to the strict technical and safety requirements.

Scope of BIS Scheme-X Certification

The Machinery and Electrical Equipment Safety (Omnibus Technical Regulation) Order, 2024, that was issued by the Ministry of Heavy Industries and implemented by the Bureau of Indian Standards (BIS), will come into effect from August 28, 2025. This order includes a wide range of products such as pumps, compressors, cranes, rotary electrical machines, transformers, switchgear, metal cutting machine (CNC). However, machinery, electrical equipment, and their parts made under Section 16 of the BIS Act, 2016, are exempt from conformity assessment. Additionally, Scheme X also applies to the construction equipment that are covered under the CMVR Rules, 1089 that were introduced by the Ministry of Road Transport and Highways (MoRTH).

This framework ensures the certified products follow strict technical and safety checks, which makes them safer and more reliable for users.

Omnibus Technical Regulation (OTR)

The Machinery and Electrical Equipment Safety (Omnibus Technical Regulation) Order, 2024 is a Technical Regulation issued by the Ministry of Heavy Industries through a gazette notification dated 28th August 2024. Its primary objective is to guarantee that the machines, electrical equipment and/or their assemblies, including the components made by the manufacturer, conform to the safety and other requirements BIS (Bureau of Indian Standards) Act and Regulations under Scheme-X.

This applies to most categories of machinery and electrical equipment, assemblies, sub-assemblies and components, but there are some key exclusions to note.The items that are already regulated under other orders issued by the BIS under Section 16 of the BIS Act, 2016, are not covered in this. Similarly, products manufactured in India solely for export and construction equipment covered under CMVR Rules, 1989 by the Ministry of Road Transport and Highways (MoRTH) are excluded.

The OTR will officially come into effect from August 28, 2025. In short, all machinery and electrical equipment mentioned in this order, along with low-voltage switchgear and control gear notified by the Ministry of Heavy Industries, will fall under Scheme X Certification by the Bureau of Indian Standards.

BIS Certification for Machinery and Electrical Equipment Safety (Omnibus Technical Regulation)

As per the Machinery and Electrical Equipment Safety (Omnibus Technical Regulation) Order, 2024, all machinery and electrical equipment, such as pumps, compressors, centrifuges, cranes, transformers, and switchgear—whether made in India or imported—must be certified by the Bureau of Indian Standards (BIS) under Scheme X.

Through this scheme, manufacturers can obtain a BIS license or Certificate of Conformity (CoC) and display the BIS Standard Mark on their products. This assures safety, quality, and consumer trust.

For micro, small and medium enterprises (MSMEs), BIS certification under Scheme X is also mandatory. It ensures their compliance with the strict safety norms as well as strengthens and maintains their credibility and competitiveness in the market.

BIS Scheme X Certification

The Bureau of Indian Standards (BIS) introduced a product certification program on March 16, 2022, called BIS Scheme X Certification, which applies to Low Voltage Switchgear, Control Gear, Machinery, and Electrical Equipment listed under the Omnibus Technical Regulation. The scheme makes it compulsory for manufacturers to follow strict safety and quality standards. All types of machine tools that are used for working on stone, ceramic, concrete, asbestos cement, or mineral glass products, along with their assemblies, must be certified under the Scheme X Certification Program before being sold in the market.

Guidelines for Using the BIS Standard Mark

- Display of the Standard Mark: The Standard Mark must be shown on the product, its packaging, or both. It can be in black & white or colored, as approved by BIS. The mark should always be clear and easy to read.

- License Number and References: The Mark shall carry the license no (CM/L-XXXXXXXXXX) and reference to the relevant standard(s) as per the license conditions.

- Certificate of Conformity (CoC): The CoC number must be present on the packaging or the product itself for which the certificate has been issued. A copy of the CoC should also be provided with the product.

- Product-Specific Labelling Requirements: BIS may introduce some extra marking or labeling requirements for certain products. Manufacturers must follow these specific rules in addition to general guidelines.

- When Physical Marking Isn’t Possible: When It’s Not Possible to Physically Mark: When it is impossible to physically print the marking on the product or packaging, it shall be printed in the test certificate delivered with the product.

- Product Information: Every detail related to the product, such as type, variety, ID number, manufacturing date/week, brand name, trademark and the address of the manufacturer, should be clearly visible on the product packaging or the label attached to it.

- When Physical Marking is Not Feasible: If the Standard Mark cannot be physically applied to the product or packaging, it must be included on the test certificate accompanying the product.

- Product Information: The product should be labeled with Type and variety, Identification number, Manufacturing date or week, Brand name and trademark, Complete address of the manufacturer.

These details should be marked on the product, packaging, or both, or included on a label attached to the product.

Key Differences Between Scheme-I & Scheme-X

Below is a comprehensive breakdown of the fees applicable for obtaining BIS Scheme X certification:

Scheme I

- For all kinds of consumer goods like electronics, appliances and industrial goods (citing the example of China, plus other regulatory bodies).

- Requires products to carry the ISI Standard Mark.

- Applicable to both Indian and foreign manufacturers.

- The certification involves factory inspections and testing of the product sample to ensure the quality is as per the standards.

Scheme X

- High-risk and industrial products such as electrical safety equipment, heavy machinery, and specialised industrial equipment.

- Requires a more difficult certification with huge documentation and full audits.

- The certification fees are higher due to the additional requirements in compliance.

- Particularly relevant for electrical equipment and industrial machinery manufacturers.

Category Of Products Listed Under Scheme-X

Scheme-X is about products with a high-risk factor, and which need to conform to heavily tested safety requirements. Some examples include:

- Electric: Industrial transformers, power supplies, high tension equipment.

- Heavy Machinery: Large presses, cranes, and automated equipment.

- Safety Devices:Fire Extinguishers, Pressure Vessels, Emergency Electrical System.

- Medical Devices: Electrical medical equipment with specific safety features.

Scheme-X is about products with a high-risk factor, and which need to conform to heavily tested safety requirements. Some examples include:

Products Covered Under Scheme-X

According to the Ministry of Heavy Industries, all kinds of low-voltage switchgear and controlgear are subject to compulsory BIS certification under Scheme-X.

| Sr No. | Indian Standards | Title of Standard | Product category | Specific Requirement |

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 |

| 1.1 (a) | IS/IEC 60947: Part 2:2016 | Low-Voltage switchgear and control gear: Part 2 circuit- Breaker (First Revision) | AC Circuit – Breakers (Category A) – All rating upto 630 A, upto 440V AC | All test as per IS/IEC 60947: Part 2: 2016 except the test listed below in Sr. No. 1.1.(b) of this table |

| 1.1 (b) | AC Circuit – Breakers (Category A) – All rating upto 630 A, upto 440V AC | Electromagnetic compatibility (EMC) mentioned in Anne J and All test specified for specific application as mentioned in the Annexure(s) of the IS/IEC 60947 : Part 2: 2016 | ||

| 1.2 (a) | AC Circuit – Breakers (Category A) – All rating above 630 A, upto 440V AC | All test as per IS/IEC 60947: Part 2: 2016 except the test listed below in Sr. No. 1.2.(b) of this table | ||

| 1.2 (b) | AC Circuit – Breakers (Category A) – All rating above 630 A, upto 440V AC | Electromagnetic compatibility (EMC) mentioned in Anne J and All test specified for specific application as mentioned in the Annexure(s) of the IS/IEC 60947 : Part 2: 2016 | ||

| 1.3 (a) | AC Circuit – Breakers (Category B)- All rating upto 2000 A, upto 440V AC | All test as per IS/IEC 60947: Part 2: 2016 except the test listed below in Sr. No. 1.3.(b) of this table | ||

| 1.3 (b) | AC Circuit – Breakers (Category B)- All rating upto 2000 A, upto 440V AC | Electromagnetic compatibility (EMC) mentioned in Anne J and All test specified for specific application as mentioned in the Annexure(s) of the IS/IEC 60947 : Part 2: 2016 | ||

| 1.4 | AC Circuit – Breakers (Category A) – All rating above 440V AC | All test as per IS/IEC 60947: Part 2: 2016 | ||

| 1.5 | AC Circuit – Breakers (Category B)- rating above 2000 A, upto 440V AC | |||

| 1.6 | AC Circuit – Breakers (Category B)- All rating above 440V AC | |||

| 1.7 | DC Circuit – Breaker (Category A) – All rating | |||

| 1.8 | AC Circuit – Breaker (Category B)- All rating | |||

| 2 | IS/IEC 60947: Part 3:2012 | Low-Voltage switchgear and control gear: Part 3 switches, disconnectors, switch disconnectors and fuse – Combination units | All types of product ratings | All test as per IS/IEC 60947: Part 3: 2012 |

| 3 | IS/IEC 60947: Part 4: Sec 1: 2012 | Low-Voltage switchgear and control gear: Part 4 contactors and motor – Starters: Sec 1 electromechanical contactors and motor – Starters (First Revision) | All test as per IS/IEC 60947: Part 4: Sec 1: 2012 | |

| 4 | IS/IEC 60947: Part 4: Sec 2: 2011 | Low-Voltage switchgear and control gear: Part 4 contactors and motor – Starters: Sec 2 a.c. semiconductor motor controllers and starters (First Revision) | All test as per IS/IEC 60947: Part 4: Sec 2: 2011 | |

| 5 | IS/IEC 60947: Part 4: Sec 3: 2014 | Low-Voltage switchgear and control gear: Part 4 contactors and motor – Starters: Sec 3 a.c. semiconductor motor controllers and contactors for non – Motor loads ( Second Revision) | All test as per IS/IEC 60947: Part 4: Sec 3: 2014 | |

| 6 | IS/IEC 60947: Part 5: Sec 1: 2009 | Low-Voltage switchgear and control gear: Part 5 control circuit devices and switching elements: Sec 1 electromechanical control circuit devices ( First Revision) | All test as per IS/IEC 60947: Part 5: Sec 1: 2009 | |

| 7 | IS/IEC 60947: Part 5: Sec 2: 2007 | Low-Voltage switchgear and control gear: Part 5 control circuit devices and switching elements: Sec 2 proximity switches | All test as per IS/IEC 60947: Part 5: Sec 2: 2007 | |

| 8 | IS/IEC 60947: Part 5: Sec 5: 2016 | Low-Voltage switchgear and control gear: Part 5 control circuit devices and switching elements: Sec 5 electrical emergency stop devices with mechanical latching function | All test as per IS/IEC 60947: Part 5: Sec 5: 2016 |

Machinery and Electrical Equipment covered under Omnibus Technical Regulation

| Sr No. | Description of Machinery and Electrical Equipment | HS Code |

| 1 | All types of Pumps for handling liquids, liquid elevators and (or) their assemblies /sub-assemblies/components | 841340, 841350, 841360, 841370, 841381, 841382 841391 and 841392. |

| 2 | All types of compressors and (or) their assemblies /sub-assemblies/components | 841430, 841440, 84148011, 84148090, 84149011,84149019, 84149040 and 84149090. |

| 3 | All types of machinery for treatment of material by a process involving a change of temperature and/or their assemblies /sub-assemblies/components | 841932, 841939,841940, 841950, 841960,841981, 841989 and 84199090. |

| 4 | All types of centrifuges, filtering or purifying machinery for liquid and gas and/or their assemblies /sub-assemblies/components | 842111, 842112, 842119, 84212110, 84212190, 842122, 842129, 842131, 842139, 842191 and 842199. |

| 5 | All types of machinery for filling, closing, sealing, labeling bottles, packing or wrapping and/or their assemblies /sub-assemblies/components | 842220, 842230, 842240 and 842290. |

| 6 | All types of cranes and (or) their assemblies /sub-assemblies/components | 842611, 842612,842619, 842620, 842630,842641, 842649, 842691 and 84269990. |

| 7 | All types of machinery for construction, earthmoving, Mining and (or) their assemblies /subassemblies/components | 8429, 843010, 843020, 843031, 843039, 843041, 843049, 843050, 843141, 843142, 843143 and 843149. |

| 8 | All types of weaving machines (looms) and (or) their assemblies /sub-assemblies /components. | 8446, 844811, 844819, 844842 and 844849. |

| 9 | All types of machinery for making embroidery and (or) their assemblies /sub-assemblies /components. | 84479020 and 844859. |

| 10 | All types of metal cutting machines tools covered under the heading 8456 to 8461 and (or) their assemblies /sub-assemblies/components | 8456, 8457, 8458, 8459, 8460, 8461 and 846693. |

| 11 | All types of machine tools for working stone, ceramics, concrete, asbestos cement or like mineral (or) and their assemblies /subassemblies /components. | 8464 and 84669100. |

| 12 | All types of machinery for working rubber and plastics and (or) their assemblies /sub-assemblies /components | 8477. |

| 13 | All types of Machines including the machines for public works & building and the machinery & mechanical appliances having individual functions, not specified Or included elsewhere in Chapter 84 and(or) their assemblies/subassemblies /components | 84791000, 84798999 and 84799090. |

| 14 | All types of gears and gearing, toothed wheels, chain sprocket, transmission elements ball or roller screws, gear boxes and speed changers, including torque converters And (or) their assemblies /sub-assemblies /components | 84834000 and 84839000. |

| 15 | All types of Rotary electrical machines such as Generator, etc and (or) their assemblies /sub-assemblies /components. | 8501 and 8503. |

| 16 | All types of Diesel Generator and (or) their assemblies /sub-assemblies /components. | 8502 and 8503. |

| 17 | All types of Transformers and (or) their assemblies /sub-assemblies /components. | 850421, 850422,850423, 850431, 850432,850433, 850434 and 850490. |

| 18 | All types of Power Semiconductor Converter and (or) their assemblies /sub-assemblies /components. | 850440 |

| 19 | All types of switch gear and control gear equipment operating at voltages not exceeding 1000 volts and (or) their assemblies /sub-assemblies /components. | 8536, 8537 and 8538. |

| 20 | All types of switch gear and control gear equipment operating at voltages exceeding 1000 volts and (or) their assemblies /sub-assemblies /components. | 8535, 8537 and 8538. |

Safety Standards Under BIS Scheme-X

BIS Scheme-X certification ensures that production is conducted under stringent safety and quality guidelines. Manufacturers are required to carry out to the following important safety standards:

- Electrical Safety: Products must meet the requirements of IEC standards to avoid difficulties such as failure, electric shock and short circuit.

- Mechanical Safety: Testing of the strength of the structure, integrity of materials, and the reliability of the device shall be subjected to a complete examination.

- Fire Safety: Flame resistance is required, and both flame spread and fire performance must be certified.

- Protect the environment: Application of energy-saving methods and the use of eco-friendly raw materials.

- Quality Management: Periodic inspection of machinery and factory premises, periodic inspections of production lines for compliance with the set BIS prototype and standards.

Compliance with Indian Standards under Scheme-X

Manufacturers should ensure their products comply with the following Indian Standards:

- Type A Standards – IS 16819:2018 / ISO 12100:2010 (Safety of Machinery – General Principles for Design, Risk Assessment & Risk Reduction).

- Type B Standards – As specified in the Second Schedule of the Omnibus Technical Regulation (OTR) Order.

- Type C Standards – As specified in the Third Schedule of the OTR Order.

- IS/IEC 60947 (Parts/Sections Various) - Low-Voltage Switchgear and Controlgear.

These safety regulations also help certified products meet legal requirements and end-user safety and product quality.

Documentation for BIS Scheme-X Certification

To obtain BIS registration for Machinery and Electricals under Scheme X (Schedule II), manufacturers must submit certain documents.

Prior Registration:

Manufacturers should submit certain information in the course of registration:

| Sr No. | Required Document | Details |

|---|---|---|

| 1 | Name, Address (Factory & Office) | Manufacturer's registered name and complete address of both factory and office. |

| 2 | PAN, GST details | Permanent Account Number (PAN) and Goods and Services Tax (GST) registration details. |

| 3 | Contact details | Email, phone number, and office contact number of the manufacturer. |

| 4 | Details of the management and authorized person | Names and designations of key management personnel and authorized signatory. |

| 5 | Details of the machinery and electrical equipment to be registered | Equipment details as per the First Schedule of the OTR. |

| 6 | Name/type and variety of products | Specific name, type, and variety of products for which BIS certification is sought. |

Registration: The organisers informed that the registration will be done online on the official portal of BIS, Manak Online. (1) This portal serves as the exclusive registration gateway for the applications for registration under the OTR.

Steps for Getting BIS Certification Under Scheme-X

The certification process for Scheme-X is threefold:

- Check Applicability - Ensure that your product comes under Scheme-X and complies with BIS Safety standards.

- Documentation Preparation – Gather all required documents, which include business license, product specification, factory layout and test reports.

- Technical File Creation – Provide an extensive compliance document consisting of product information, manufacturing methods, QC methodologies, product scope description, and supporting documents. It should also mention your test reports, raw material used and the name of your sub-contract, if any, along with all the traceability details.

- Apply - Register on the BIS official website and complete your online application, and pay the fee.

- Factory Inspection – BIS officers visit the factory (2 days for Indian manufacturers, 3 days for foreigners). They audit procedures, technical documentation, quality procedures, watch testing and observe non-conformity before presenting their report.

- Sample Checking – Samples of the product are checked at the site or at BIS-approved laboratories.

- Grant of License by BIS – After satisfactory compliance with requirements, BIS issues a licence to the manufacturer to use the BIS Standard Mark.

Procedure of BIS Scheme-X Certification

The BIS Scheme-X certification process applies to both domestic and foreign manufacturers.

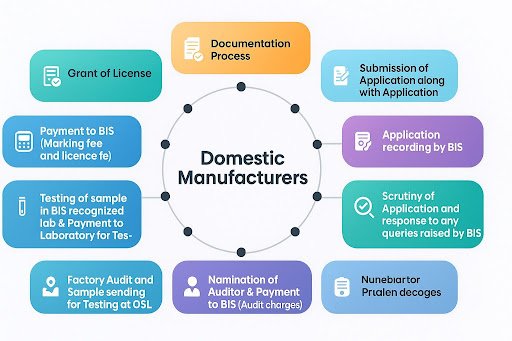

Procedure for Grant of Licence for Domestic Manufacturers

The following steps will take place for the Domestic Manufacturers mentioned below:

- Documentation - Prepare all required documents for certification.

- Application Submission – Apply along with the prescribed application fee.

- Application Recording – BIS records the application for further processing.

- Scrutiny & Queries – BIS reviews the application and raises queries, if any, which must be addressed by the applicant.

- Auditor Nomination & Fee Payment – BIS nominates an auditor, and the applicant pays the audit charges.

- Factory Audit & Sample Collection - The factory is visited, and product samples are taken for testing at an Outside Testing Laboratory (OSL).

- Sample testing - Samples are tested at BIS-recognised labs at the manufacturer's cost (subcontracted labs may vary).

- Fees - Applicant is charged the BIS marking and license fee.

- Granting of License – After verification, a license is granted by BIS.

- Overall Timeline - The complete process of certification generally takes up to around 90 working days in accordance with the BIS standards.

Procedure of BIS Scheme-X Certification

The following steps will take place for the Foreign Manufacturers mentioned below:

- Documentation - All documents need to be prepared and placed in sequence with the requirements.

- Apply - File the application with the requisite fees.

- Recording of Application - The BIS shall receive the application and record it for processing.

- Scrutiny & Queries – BIS shall process the application and raise questions for clarity, if any.

- Auditor Nomination & Fee Payment – BIS nominates an auditor, and the applicant pays the audit charges.

- Factory Audit & Sample Collection – The factory is inspected, and product samples are collected for testing at an Outside Testing Laboratory (OSL).

- Sample Testing – Samples are tested in BIS-approved labs, with testing fees paid by the manufacturer (subcontracted facilities may vary).

- Payment of Fees - The applicant pays the marking fee and license fee to BIS.

- Grant of Licence – After successful verification, BIS issues the license.

General Timeline: The certification process for foreign manufacturers usually takes 6–7 months as per current BIS practices.

Documentation for BIS Scheme-X Certification

- Under FMCS norms, all foreign manufacturers are treated as ‘Large Scale’ units, regardless of their actual production size.

- Foreign manufacturers are required to appoint an Authorised Indian Representative (AIR) who will coordinate with BIS and handle the operations and maintenance of the BIS license.

- For foreign manufacturers, the factory audit includes on-site inspections and product sample testing in BIS-recognised laboratories. The audit usually takes about 3 days, and extra applications may require additional audit days.

BIS Scheme-X Certification Fee

To obtain certification under Scheme-X, manufacturers are required to follow the prescribed fee structure. According to Schedule-II, Scheme-X, Paragraph 5 of the Bureau of Indian Standards (Conformity Assessment) Regulations, 2018, BIS has outlined a standard fee system. This structure applies to products or product groups when no separate fee notice is informally published. The objective is to streamline the certification procedure and also bring uniformity in charges for manufacturers who are making an application for BIS Scheme-X certification.

| Sr No. | Types of Fees / Charges | Amount |

| 1 | Application Fee for Grant of License | ₹2,000 |

| 2 | Application Fee for Certificate of Conformity | ₹2,000 |

| 3 | Certification Fee for License Grant or Renewal | ₹25,000 per year |

| 4 | Certification Fee for Certificate of Conformity | ₹10,000 |

| 5 | Technical File Review Fee (for license, certificate, or scope changes) | ₹20,000 per technical file |

| 6 | Inspection Fees (Including Surveillance) | ₹20,000 per man-day |

| 7 | Sample Procurement Charges | Based on actual costs |

| 8 | Testing Charges | Based on actual costs |

The Validity and Renewal Procedure of the Scheme-X Certificate

- License Validity & Renewal: Licenses are valid for 3-6 years for sustained production. These can be extended for the same period under the application.

- Certificate of Conformity (CoC): The certificate is valid for single manufacturing and is mandatory for India and overseas manufacturers. It cannot be renewed.

- Product Test reports: If an in-house laboratory is used by a manufacturer, BIS officials will witness the testing during the factory audit. If there are subcontracted labs, they will also be visited to ensure they are compliant.

Manufacturers must strictly follow the Scheme-X certification process to maintain product approval. The Bureau of Indian Standards (BIS) reviews renewal applications and issues renewed licenses using Form VIII, as per Regulation 8 of the applicable rules.

Conclusion

BIS Scheme-X Certification is essential to guarantee the safety and quality of low-voltage switchgear, control gear, machinery, and electrical equipment. This certification ensures that manufacturers comply with strict Indian standards while streamlining the production process.

Stone, Ceramic, Concrete, Asbestos Cement & Mineral Glass Product Processing Machinery will have to be certified under Scheme-X. It not only enhances product durability, but also builds greater trust and confidence among users.

Contact EVTL India, a leading BIS Scheme-X certification consultant, to make the certification process simple and hassle-free. With years of expertise in testing, inspection, and regulatory compliance, EVTL India provides complete support to manufacturers and importers.

For guidance with documentation, testing, and application processing, reach out to EVTL India at contact@evtlindia.com.