Get A Quote

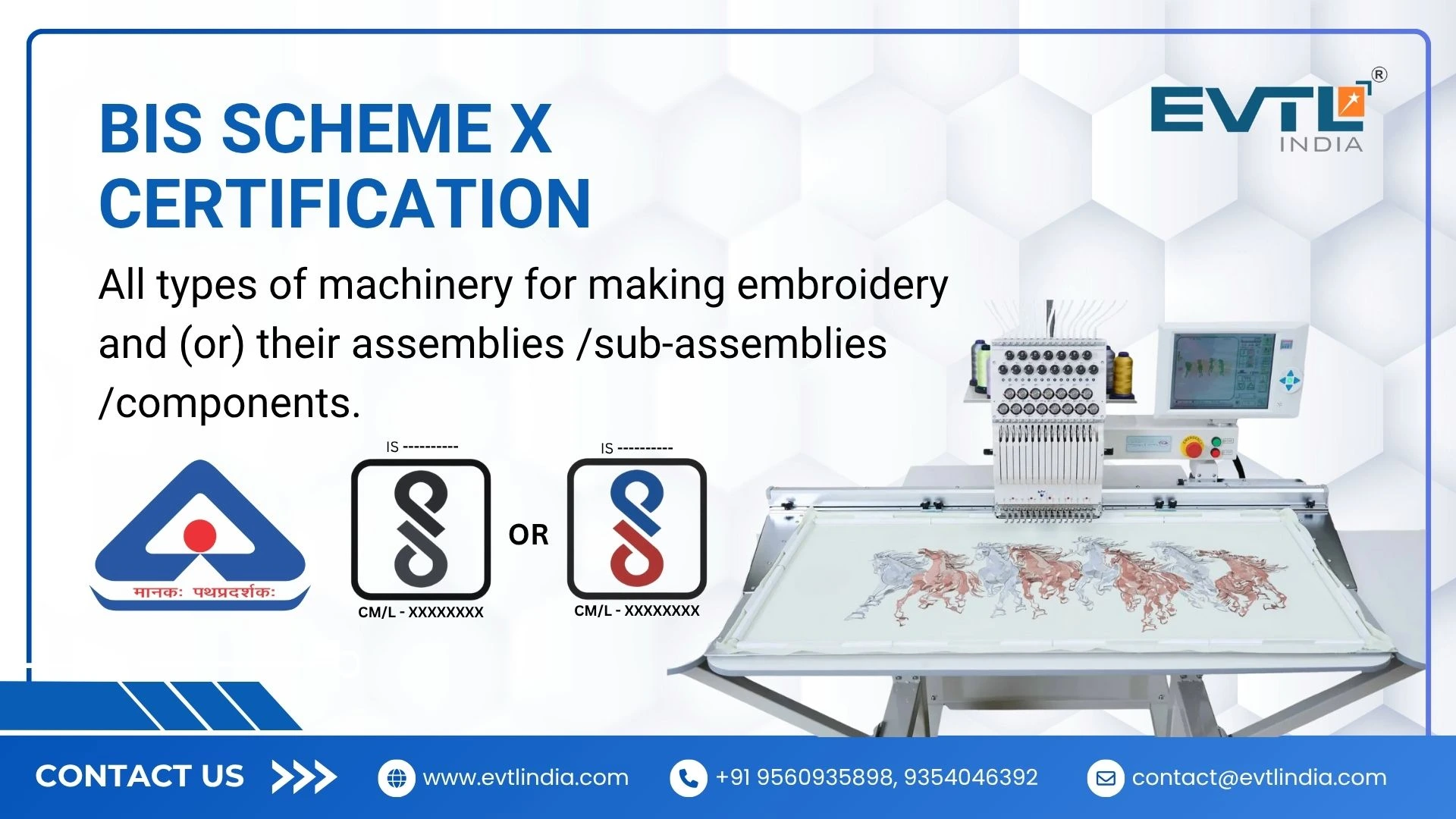

BIS Certification for Machinery for Making Embroidery

India’s textile industry has always

been a strong pillar of the nation’s economic and cultural identity, with

embroidery playing a central role in both traditional and modern textile

design. As the demand for high-quality embroidered garments and home

furnishings grows globally, the machinery used to produce such embroidery must

align with rigorous quality, safety, and performance standards. To regulate and

enhance the manufacturing quality of embroidery machinery and its components,

the Bureau of Indian Standards (BIS) has introduced Scheme X Certification, a

dedicated framework under its conformity assessment regulations.

Let’s explore the scope, importance, and process of BIS certification for machinery for making embroidery, with a special focus on BIS Scheme X Certification and its implications for manufacturers.

What is the

BIS Scheme X Certification?

Scheme X Certification is an

initiative launched by the Bureau of Indian Standards (BIS) on 16th March 2022,

as part of the BIS Conformity Assessment Regulations, 2018. This scheme is

specifically designed for machinery and electrical equipment to ensure that

their safety, quality, and performance conform to Indian Standards.

The certification is now a mandatory requirement, as per the Omnibus Technical Regulation Order, 2024, issued by the Ministry of Heavy Industries. All domestic and international manufacturers of embroidery machinery and their assemblies/subassemblies/components must comply with BIS Scheme X Certification by 28th August 2025.

Scope of

Certification

The BIS certification for machinery

for making embroidery covers a broad category of machines and associated

components, including:

These machines, regardless of their origin (manufactured in India or imported), must adhere to the safety, efficiency, and durability criteria outlined by the relevant Indian Standards under Scheme X Certification.

Why is BIS

Certification Important for Embroidery Machinery?

- Ensures Product SafetyEmbroidery machines often run at high speeds and involve complex electrical and mechanical systems. BIS certification ensures that all machinery adheres to safety protocols, reducing the risks of malfunctions, electric shocks, or accidents.

- Assures Quality ComplianceUniform performance standards foster consistency in embroidery quality, reducing machine downtime and ensuring durability.

- Mandatory by LawUnder the Omnibus Technical Regulation Order, 2024, compliance with BIS Scheme X certification for machinery for making embroidery is no longer optional. Non-compliance can lead to penalties, import restrictions, or business shutdowns.

- Boosts Global and Domestic Market AccessA BIS-certified embroidery machine is more trusted in the market. It enhances brand reputation and enables smoother entry into government procurement systems and export channels.

- Supports Make in India and Quality India InitiativesStandardized and certified machines support the Government of India’s initiatives to promote quality manufacturing within the country.

The Indian Standards applicable to

embroidery machines typically focus on:

Certification

Process – Step-by-Step

To obtain BIS Scheme X certification

for embroidery machinery, manufacturers must follow a well-defined process:

1. Application Submission

The process begins with applying to

BIS. This includes:

2. Sample Testing

Samples of the machinery or components

are sent to BIS-recognized laboratories for testing. The equipment is checked

for compliance with applicable Indian Standards.

3. Factory Inspection

BIS officials conduct on-site factory

audits to verify:

4. Grant of Certification

If all parameters meet the criteria,

the manufacturer is granted a BIS certification license under Scheme X. The

Standard Mark (ISI mark) is then allowed to be affixed to the certified

equipment.

5. Surveillance and Renewal

BIS conducts periodic surveillance audits to ensure that compliance is maintained. Renewals are typically required every 1-2 years, depending on performance and compliance history.

How to Prepare

for BIS Scheme X Certification

To ensure a smooth transition to

compliance, manufacturers are advised to:

- Start Early: Begin documentation and initial testing well ahead of time.

- Conduct Internal Audits: Evaluate current practices and identify gaps with respect to BIS standards.

- Engage BIS Consultants: Professional consultants can help navigate technical details, prepare applications, and coordinate with BIS.

- Upgrade Quality Systems: Invest in better quality control and testing infrastructure.

- Train Staff: Educate your team about the significance of compliance and safety practices.

BIS Marking

and Labeling

Once certified, all embroidery

machines and applicable parts must be marked with:

This marking must be visible, permanent, and legible to avoid violations during inspections or post-market surveillance.

Conclusion

The textile and garment industry is

evolving rapidly, and high-precision embroidery machines are central to this

transformation. To meet the demands of safety, quality, and international

competitiveness, the BIS certification for machinery for making embroidery is

now a legal and commercial necessity.

By obtaining BIS Scheme X

certification for embroidery machinery, manufacturers ensure their products are

legally compliant, technically superior, and trusted by customers. As the 28th

August 2025 deadline draws closer, it’s essential for all stakeholders—from

large manufacturers to small OEMs—to embrace the certification process.

BIS is not just about regulation—it’s

about ensuring India's manufacturing sector operates at par with global

standards.

If you are a manufacturer, importer,

or supplier of embroidery machinery and components and are seeking guidance on

BIS Scheme X certification, now is the right time to act. Partner with EVTL

India, experienced BIS consultants, to begin your certification journey. Let

your embroidery machines not just stitch designs, but also a seal of quality,

safety, and trust.

You can contact us via email at contact@evtlindia.com or by phone at 9560935898. Feel free to get in touch with us anytime for the support you need.

BIS ISI Mark Certification | BIS-CRS Certification | EPR E-WASTE | WMI Registration | BIS Certification For Footwear | TAC & IMEI Registration | BIS FMCS Page | TEC | EPR Registration for Plastic Waste Management | EPR Registration for Battery Waste Management | EPR Registration For Used Oil | EPR Registration for Tyre Waste Management | WPC ETA License | NOC | LMPC | Legal Metrology | Trademark Registration | ISO Certification | EMI-EMC Test | Toys | GEM Registration | EPCG Scheme | LM 79 & LM 80 | ROHS Approval | CDSCO Registration | RF Testing | IP Rating Test | MSME & NSIC Registration | BIS Certificate for Conformity | BIS Scheme-X Certification | Hallmark Registration | Laboratory Recognition Scheme | ECO-MARK Certification | RDSO | CE Certification | List Of Equipments | US FDA Registration | Lab Setup & Lab Equipment |

Product Under Scheme X

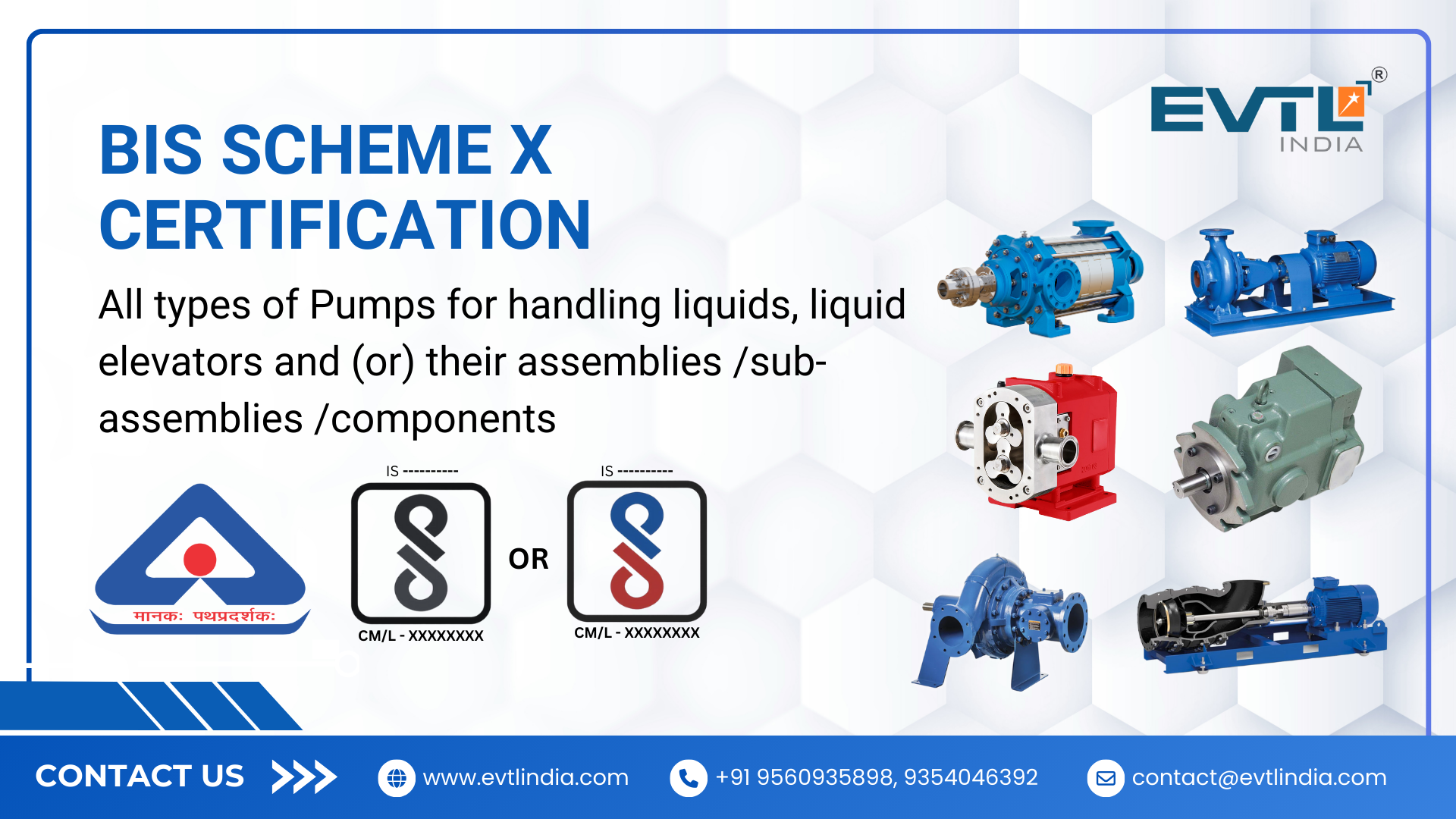

BIS Scheme X Certification for Pumps and Liquid Elevators

BIS Scheme X Certification for Compressors

BIS Scheme X certification for Heat Treatment Equipment

BIS Scheme X Certification for Centrifuges and Filtering or Purifying Machinery

BIS Scheme X Certification for Machinery for Filling, Closing, Sealing, Labelling Bottles, Packing or Wrapping

BIS Scheme X Certification for Cranes and Their Assemblies, Sub-Assemblies, or Components

BIS Scheme X Certification for Construction, Earthmoving, and Mining Machinery

BIS Scheme X Certification for Weaving Machines (Looms)

BIS Certification for Machinery for Making Embroidery

BIS Scheme X Certification for Metal Cutting Machine Tools (HS Codes 8456–8461)

BIS Scheme X Certification for Machine Tools Working on Stone, Ceramics, Concrete, Asbestos Cement, and Similar Materials

BIS Scheme X Certification for Machinery for Working Rubber and Plastics

BIS Scheme X Certification for Machines for Public Works, Building, and Other Mechanical Appliances

BIS Scheme X Certification for Gears, Gearing, and Transmission Elements

BIS Certification for Rotary Electrical Machines, such as Generators, etc

BIS Scheme X Certification for Diesel Generators and Their Components

BIS Scheme X Certification for Power Semiconductor Converters

BIS Certification for Transformers and Their Components

BIS Scheme X Certification for Switchgear and Controlgear Equipment (≤1000V)

BIS Certification for Switchgear and Controlgear Equipment Operating Above 1000 Volts