Get A Quote

BIS Certification for Valve Fittings for LPG Cylinders Above 5 Litres IS 8737:2017

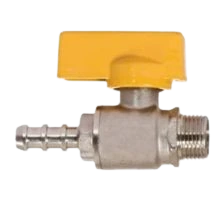

Valve fittings are the most critical

components of LPG cylinders. They control the flow of gas, ensure safety during

use, and prevent gas leaks or pressure-related accidents. In India, for LPG cylinders with a water capacity

exceeding 5 litres, the Bureau of

Indian Standards (BIS) mandates compliance with IS 8737:2017, a standard that ensures the performance, safety, and

durability of valve fittings used in such cylinders.

This certification is not merely a regulatory formality—it is a necessary safety mechanism. LPG is a highly flammable fuel, and any failure in the valve system could result in serious fire hazards, explosions, or toxic exposure. Hence, the quality of valve fittings, particularly those used in high-pressure environments, is stringently regulated by BIS through this standard.

Importance of IS 8737:2017

for LPG Valve Fittings

IS 8737:2017 lays down the

specifications for valve fittings used in LPG cylinders exceeding 5 litres of

water capacity, commonly used in domestic, commercial, and industrial sectors.

These valves are responsible for safe filling, storage, and regulated

withdrawal of gas. The standard outlines all aspects of design and performance,

right from the materials used, structural design, and valve stem threading, to

pressure-bearing capabilities, durability, and resistance to corrosion and

impact.

This ensures that the valves can endure high internal pressures, external physical impacts, long-term operational stress, and exposure to environmental conditions—all while maintaining leak-proof and safe performance throughout the cylinder’s service life.

Scope of IS 8737:2017

The IS 8737:2017 standard is

comprehensive and applies to newly

manufactured valves that are intended for installation on LPG cylinders. It

encompasses:

The standard is often used in conjunction with IS 3196, IS 4576, and other relevant codes to ensure a complete safety framework for LPG storage and distribution systems.

Why BIS Certification is

Mandatory

According to the Gas Cylinders Rules and quality control orders issued by the Department for Promotion of Industry and

Internal Trade (DPIIT), compliance with IS 8737:2017 and BIS certification

is mandatory for all manufacturers and suppliers of LPG valve fittings in

India.

The BIS ISI mark on a valve fitting

confirms:

Without this certification, the valve fitting cannot legally be marketed or used in LPG systems in India, especially by oil companies, government suppliers, or licensed LPG distributors.

Tests Conducted as per IS

8737:2017

To ensure complete reliability, IS

8737:2017 requires that valve fittings undergo a series of stringent mechanical,

chemical, and performance tests. These are conducted in BIS-approved

laboratories and include:

These tests reflect real-world conditions and operational stresses to guarantee the safety of every valve approved under this standard.

BIS Certification Process

Manufacturers who wish to obtain BIS

certification for valve fittings under IS 8737:2017 must go through the

following steps:

- Application Filing with BIS, including product and factory details.

- Product Testing at a BIS-recognized laboratory.

- Factory Audit to evaluate production infrastructure, quality management systems, and in-house testing capabilities.

- Grant of BIS License after successful inspection and testing.

- Use of the ISI Mark on certified valve fittings with an assigned license number.

- Surveillance Audits and Renewal at regular intervals to maintain compliance.

The BIS license is only issued when the manufacturer demonstrates consistent adherence to quality control and traceability systems, along with passing the mandatory tests under IS 8737:2017.

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Documents Required for BIS Certification

To apply for BIS certification, manufacturers need to submit the following documents:

● Application form

● Manufacturing process details

● Quality control plan

● Test reports from BIS-approved laboratories

● Factory layout and equipment details

● Proof of business registration

● Product specifications and technical details

● Declaration of conformity to Indian standards

Additionally, manufacturers may be required to provide proof of compliance with environmental and safety regulations, depending on the specific type of product being certified.

BIS ISI Mark Certification Costing And Timeline

Conclusion

Valve fittings for LPG cylinders above

5-litre capacity are vital for safe gas storage and distribution. Given the

hazardous nature of LPG, these fittings must meet the highest standards of

performance and reliability. IS 8737:2017, established by the Bureau of Indian

Standards, provides a robust framework for ensuring safety, quality, and

consistency in these components.

BIS certification under this standard

is not optional—it is a regulatory requirement for any manufacturer or supplier

intending to participate in India’s LPG ecosystem. It not only ensures

compliance with legal norms but also builds confidence among consumers and

government procurement agencies regarding the safety of their LPG

infrastructure.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile