Get A Quote

BIS Certification for Steel Wire Rope Net Panels and Rolls IS/ISO 17746:2016

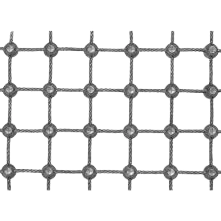

In modern geotechnical engineering and

infrastructure safety systems, steel

wire rope net panels and rolls have become essential components. Used

predominantly for slope stabilization,

rockfall protection, and debris flow mitigation, these flexible

protective structures are deployed across roadways, railways, construction

sites, and mining areas. Their function is critical—safeguarding lives,

property, and infrastructure from natural hazards.

With the growing emphasis on structural safety and standardization, the Ministry of Commerce and Industry has issued a draft Quality Control Order (QCO), 2025, making BIS certification mandatory for steel wire rope net panels and rolls. This certification ensures compliance with the Indian Standard IS/ISO 17746:2016, which defines the essential requirements, testing methods, and quality specifications for these products.

Understanding Steel Wire

Rope Net Panels and Rolls

Steel wire rope nets are constructed

using metallic-coated steel wire ropes,

configured in either panel or roll form. These nets form a flexible yet strong

mesh that adapts to irregular terrain and absorbs dynamic forces from falling

rocks or debris. Their high tensile strength and corrosion resistance make them

particularly suitable for long-term outdoor installations in harsh

environmental conditions.

The panel form of rope nets is pre-assembled and used for precise applications such as hanging net systems or tensioned barriers, while rolls are generally more flexible and adaptable to a variety of site conditions. Both formats provide essential protection in areas where traditional rigid barriers or concrete structures are either impractical or ineffective.

Scope of IS/ISO 17746:2016

The Indian Standard IS/ISO 17746:2016, titled “Steel Wire Rope Net Panels and Rolls —

Definitions and Specifications”, is aligned with the international ISO

standard and establishes uniform quality benchmarks for these safety-critical

products.

This standard applies to:

The standard includes definitions, structural requirements, materials, coating specifications, and test methods, ensuring that the net panels and rolls meet critical performance parameters.

Key Performance and

Testing Parameters

To meet the requirements of IS/ISO

17746:2016 and qualify for BIS

certification, steel wire rope net panels and rolls must undergo rigorous

testing. These tests evaluate both the mechanical

integrity and coating quality of

the wire rope materials. Some of the crucial tests include:

Additionally, dimensional tolerances, wire rope diameters, net aperture sizes, and mesh configurations are also checked for conformity with the design specifications outlined in the standard.

BIS Certification and

Regulatory Compliance

Under the proposed Quality Control Order (QCO), 2025,

steel wire rope net panels and rolls must obtain BIS certification before being manufactured, imported, or sold in

the Indian market. This move is part of the government’s broader effort to

enhance infrastructure safety by standardizing construction materials and

enforcing quality benchmarks.

Key aspects of the BIS certification

process include:

The order excludes goods that are

manufactured in India exclusively for export, allowing exporters to continue

meeting the specific standards of foreign markets.

BIS Certification Process for Locknuts and Locking Devices

BIS certification under this standard

involves a rigorous conformity assessment process to ensure product quality and

adherence to regulatory norms. The steps typically include:

- Filing an application to BIS with detailed product specifications, quality management system documents, and test reports.

- Factory inspection by BIS auditors to verify manufacturing capability, equipment, testing infrastructure, and quality controls.

- Product testing of locknuts and locking devices at BIS-recognized laboratories to confirm compliance with IS 16605 (Part 2):2018.

- Grant of BIS License upon successful audit and testing.

- Ongoing surveillance by BIS to ensure continued compliance through periodic inspections and testing of market samples.

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Documents Required for BIS Certification

To apply for BIS certification, manufacturers need to submit the following documents:

● Application form

● Manufacturing process details

● Quality control plan

● Test reports from BIS-approved laboratories

● Factory layout and equipment details

● Proof of business registration

● Product specifications and technical details

● Declaration of conformity to Indian standards

Additionally, manufacturers may be required to provide proof of compliance with environmental and safety regulations, depending on the specific type of product being certified.

BIS ISI Mark Certification Costing And Timeline

Why Compliance Matters

Steel wire rope net panels and rolls

are not decorative accessories—they serve as the first line of defense in preventing fatalities, asset loss, and

infrastructure failure due to natural hazards. A failure in the performance of

such components can result in devastating outcomes. The BIS certification ensures that only verified, high-quality products

are installed in critical infrastructure projects.

For infrastructure developers, public works departments, and private contractors, using BIS-certified materials ensures not only compliance with national regulations but also instills trust among stakeholders. It also facilitates smoother project approvals, especially in government-funded works or those involving environmental clearances.

Conclusion

With India’s expanding road and rail

networks cutting through hilly and geologically unstable terrain, the demand

for high-performance protective systems like steel wire rope nets is steadily

increasing. The implementation of BIS

certification under IS/ISO 17746:2016 marks a significant step toward

enhancing safety, reliability, and uniformity across all such installations.

Manufacturers and suppliers must act

swiftly to align their production with the BIS standards to remain competitive

and legally compliant in the Indian market.

EVTL India is your trusted regulatory

compliance partner, offering end-to-end consultancy for BIS certification of Steel Wire Rope Net Panels and Rolls. From

product testing to documentation, factory audits to post-certification

assistance—we handle it all.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile