Get A Quote

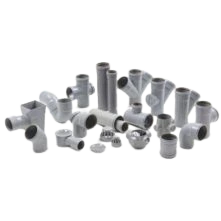

BIS Certification for Injection Moulded PVC Socket Fittings With Solvent Cement Joints for Water Supplies IS 7834 Part 3 – 90 Degree Elbows

When it comes to designing effective

water supply systems, the quality and compatibility of fittings are as crucial

as the pipes themselves. One of the most commonly used components in these

systems is the 90-degree elbow, essential for changing pipe direction without

compromising water flow or pressure.

In India, these elbows must conform to

IS 7834 (Part 3) to ensure performance, safety, and durability. That’s where

the BIS certification for Injection Moulded PVC Socket Fittings With Solvent

Cement Joints For Water Supplies becomes critical.

Having the ISI mark on your fittings is more than just a legal formality; it’s a competitive advantage. The mark assures consumers, engineers, and contractors that your product meets the Indian standard for Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Supplies, is safe for use in potable water applications, and has passed rigorous performance and durability tests.

Indian Standard IS 7834

Part 3

IS 7834 (Part 3) specifically

addresses 90-degree elbow fittings made from PVC that are designed for

socket-type joints using solvent cement. This section of the standard outlines

the specific requirements regarding the shape, size, wall thickness, mechanical

strength, hydraulic performance, and long-term durability of these fittings.

It specifically covers 90-degree injection-molded elbow fittings with solvent cement socket joints, intended for use in cold potable water supply systems, as well as in both above-ground and underground piping networks. By adhering to the Indian standard for Injection Moulded PVC Socket Fittings with Solvent Cement Joints for Water Supplies, manufacturers can ensure that their products are safe, reliable, and suitable for pressurized water supply systems.

Why is BIS Certification

Important?

The Bureau of Indian Standards (BIS)

is India’s national standards body responsible for ensuring product quality

through certification schemes. For PVC fittings, including 90-degree elbows,

obtaining BIS certification is both a compliance necessity and a mark of

trustworthiness.

Here’s why it matters:

Steps to Obtain BIS

Certification

To obtain BIS certification for

Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water

Supplies, manufacturers need to follow a systematic process:

- Application

Submission: Submit the completed application

form with necessary documentation to BIS.

- Document Review: BIS evaluates the submitted documents to verify accuracy and

completeness.

- Factory Inspection: BIS officials conduct on-site inspections to assess

manufacturing processes and quality control systems.

- Sample Testing: Product samples are collected and tested at BIS-approved

laboratories to verify compliance with Indian standards.

- Certification Grant: Upon successful inspection and testing, the BIS issues the certification, allowing the use of the ISI Mark.

Documents Required for BIS Certification

To apply for ISI

Certification for Injection Moulded PVC Socket Fittings With Solvent Cement

Joints For Water Supplies, manufacturers must provide the following documents:

● Completed application form

● Detailed manufacturing process

information

● Quality control plans and test

reports

● Factory layout and equipment

details

● Product specifications and

technical details

● Business registration proof

● Declaration of conformity to

Indian standards

BIS ISI Mark Certification Costing And Timeline

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Conclusion

For manufacturers of 90-degree elbow

fittings, aligning with IS 7834 Part 3 and securing BIS certification is a step

toward credibility, trust, and expanded market access. With water

infrastructure becoming more vital than ever, customers prefer fittings that

carry the ISI mark certification, a testament to long-lasting quality. Want

expert guidance on securing BIS certification for your PVC fittings? Get in

touch with our team for a seamless, end-to-end support experience—from

documentation to ISI mark certification.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile