Get A Quote

BIS Certification for Plummer Block Housings IS 14347:1996

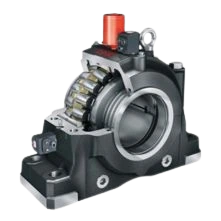

In the world of industrial machinery and mechanical systems, bearing housings serve a critical role in supporting and securing rotating shafts. Among the various types, plummer block housings—also commonly known as pillow block housings—are among the most widely used. These essential components are engineered to house bearings and provide firm, aligned support for shafts, especially in environments subjected to heavy loads and continuous motion.

To ensure the structural reliability, dimensional compatibility, and long-term performance of these housing units, the Bureau of Indian Standards (BIS) has formulated a dedicated Indian Standard—IS 14347:1996. This standard outlines the specifications, design parameters, and material requirements for plummer block housings and related bearing accessories used across industries.

What Are Plummer Block

Housings?

Plummer block housings are specially

designed casings that support a rotating shaft by holding and protecting the

bearing unit. They are typically made of cast iron or cast steel, offering a durable

shell for the bearing while allowing easy installation, lubrication, and

maintenance.

These housings are used in a wide

variety of industrial applications, including:

Plummer block housings can accommodate several types of rolling bearings—most commonly self-aligning ball bearings and spherical roller bearings—enabling them to handle heavy radial loads and moderate axial loads. Their design also allows for slight shaft misalignment, which enhances operational flexibility in rugged environments.

Overview of IS 14347:1996

The Indian Standard IS 14347:1996 provides comprehensive

guidelines for the design, dimensions,

tolerances, and material quality of plummer block housings. It applies not

only to standard plummer block housings but also to related units such as flanged housings and take-up housings.

This standard ensures uniformity and

interchangeability of components across manufacturers while maintaining high

levels of mechanical performance and durability. The specifications also take

into account environmental exposure, vibration, and loading conditions under

which these housings operate.

Key features covered in IS 14347:1996

include:

Regulatory Mandate Under

the Quality Control Order, 2025

As part of its ongoing efforts to

strengthen product quality and eliminate substandard mechanical components, the

Ministry of Commerce and Industry

has issued the Bearing Components and

Accessories (Quality Control) Order, 2025. This order mandates that several

bearing-related components, including plummer

block housings, must comply with their respective Indian Standards and be

certified under the Bureau of Indian

Standards (BIS).

Under this order:

The certification process is governed by Scheme-I of Schedule-II of the BIS (Conformity Assessment) Regulations, 2018, which lays down the procedures for product testing, factory inspection, and ongoing surveillance.

BIS Certification Process for Plummer Block Housings

To obtain the BIS license for plummer

block housings under IS 14347:1996, manufacturers must go through a detailed

conformity assessment that ensures product compliance with every aspect of the

standard.

The certification process typically

includes:

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Documents Required for BIS Certification

To apply for BIS certification, manufacturers need to submit the following documents:

● Application form

● Manufacturing process details

● Quality control plan

● Test reports from BIS-approved laboratories

● Factory layout and equipment details

● Proof of business registration

● Product specifications and technical details

● Declaration of conformity to Indian standards

Additionally, manufacturers may be required to provide proof of compliance with environmental and safety regulations, depending on the specific type of product being certified.

BIS ISI Mark Certification Costing And Timeline

Why BIS Certification Matters

For industries that rely on rotating

machinery and heavy-duty mechanical assemblies, product failure or misalignment due to inferior housing components

can lead to costly downtime, safety hazards, and equipment damage. BIS

certification mitigates these risks by enforcing a national benchmark of

quality and compatibility.

For manufacturers, the certification:

For end users and buyers, it assures that the product is safe, reliable, and dimensionally compatible with other standard mechanical components.

Conclusion

Plummer block housings might appear to

be simple mechanical parts, but their design, performance, and durability are

critical to the health of rotating equipment. With the implementation of the

Bearing Components and Accessories (Quality Control) Order, 2025, and the

mandatory enforcement of IS 14347:1996, BIS certification has become a crucial

step for manufacturers and suppliers dealing in these components.

By ensuring compliance with BIS

standards, industries can maintain mechanical integrity, enhance operational

safety, and align with national and international benchmarks of quality.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile