Get A Quote

BIS Certification for Needle Rollers for Rolling Bearings IS 4217:2020

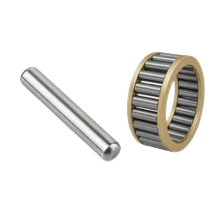

In the world of precision engineering,

needle roller bearings stand out for

their unique design and exceptional performance in compact spaces. At the core

of these bearings are needle rollers—slender,

cylindrical rolling elements that are critical to the functionality and

durability of the entire assembly.

These components are essential in applications where space is limited but performance cannot be compromised, such as in gearboxes, two-wheelers, automotive transmissions, machine tools, packaging machinery, and industrial automation systems.

Recognizing the importance of standardizing the quality and performance of needle rollers, the Bureau of Indian Standards (BIS) has specified detailed requirements under IS 4217:2020. This standard outlines the technical specifications, testing protocols, and quality parameters necessary for manufacturing needle rollers that meet the demands of modern industry.

Understanding the Role of

Needle Rollers

Needle rollers are distinguished by

their small diameter-to-length ratio,

which gives them a “needle-like” appearance. Despite their slender design,

these rollers are capable of handling high

radial loads due to the increased contact area they provide within the

bearing assembly. This makes them ideal for applications where conventional

cylindrical rollers would not fit.

These rollers must be manufactured to high degrees of accuracy in terms of dimensions, roundness, surface finish, and hardness. Even minor deviations can significantly affect bearing performance, leading to premature wear, noise, or failure.

IS 4217:2020 – Standard

Specifications for Needle Rollers

The Indian Standard IS 4217:2020, developed by BIS,

specifies the characteristics and performance requirements for needle rollers

used in rolling bearings. It serves as a national benchmark and aligns with

international practices to ensure consistency, reliability, and compatibility

in global and domestic supply chains.

Key aspects addressed by the standard

include:

By complying with IS 4217:2020, manufacturers can assure the mechanical precision and functional reliability of needle rollers used in high-stress applications.

Mandatory BIS

Certification Under Quality Control Order, 2025

To regulate the quality of rolling

bearing components in India, the Ministry of Commerce and Industry has

introduced the Bearing Components and Accessories (Quality Control) Order,

2025. As per this order, manufacturers, importers, and suppliers must ensure that

needle rollers for rolling bearings conform to IS 4217:2020 and are certified

by the Bureau of Indian Standards.

Under this regulation:

This move not only raises the bar for product quality and safety but also helps protect industries and end-users from substandard or counterfeit components.

BIS Certification Process for Needle Rollers

- Application Submission: The manufacturer submits a detailed application with technical documents and quality assurance plans.

- Factory Audit: BIS officials inspect the manufacturing facility to assess the production process, quality control systems, and testing infrastructure.

- Product Sampling and Testing: Samples are taken for evaluation at BIS-recognized laboratories. The products are tested for dimensional accuracy, surface characteristics, hardness, and performance benchmarks.

- License Grant: If the product meets all requirements, BIS grants a license, allowing the use of the ISI mark.

- Ongoing Surveillance: The certified facility undergoes regular audits and surveillance to maintain certification.

This rigorous approach ensures that only compliant products enter the market, offering consistent performance and long-term reliability.

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Documents Required for BIS Certification

To apply for BIS certification, manufacturers need to submit the following documents:

● Application form

● Manufacturing process details

● Quality control plan

● Test reports from BIS-approved laboratories

● Factory layout and equipment details

● Proof of business registration

● Product specifications and technical details

● Declaration of conformity to Indian standards

Additionally, manufacturers may be required to provide proof of compliance with environmental and safety regulations, depending on the specific type of product being certified.

BIS ISI Mark Certification Costing And Timeline

Importance of Certification for Industry Stakeholders

For manufacturers, BIS certification

under IS 4217:2020 provides a competitive advantage by demonstrating compliance

with national standards and enhancing trust with clients. It facilitates access

to government tenders, industrial supply chains, and international markets.

For end-users, OEMs, and system integrators, the ISI mark guarantees that the needle rollers they use are tested for precision, strength, and durability, reducing the risk of operational failure and maintenance costs.

Conclusion

Needle rollers may appear simple, but

their performance directly influences the reliability of critical mechanical

systems. With the implementation of IS 4217:2020 and its mandatory

certification under the Quality Control Order, 2025, India is taking a major

step toward ensuring the quality, safety, and global competitiveness of its

engineering components.

Whether you are a manufacturer seeking

certification or an industry buyer sourcing reliable components, BIS compliance

is not just a regulatory need—it is a quality assurance that defines the future

of precision engineering in India.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile