Get A Quote

BIS Certification for Injection Moulded PVC Socket Fittings with Solvent Cement Joints for Water Supplies IS 7834 (Part 1)

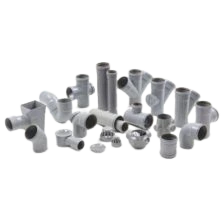

Injection moulded PVC socket fittings

play a critical role in ensuring leak-proof and durable water supply systems.

These fittings, when used with solvent cement joints, create strong connections

that are vital for plumbing infrastructure in residential, commercial, and

industrial buildings.

To ensure the safety, reliability, and

standardization of these products in India, manufacturers must obtain the BIS

certification for Injection Moulded PVC Socket Fittings with Solvent Cement

Joints for Water Supplies. This certification is granted based on compliance

with the applicable Indian Standard IS 7834 (Part 1), which outlines the

general requirements for such fittings.

The ISI mark is a trusted symbol of quality and safety in the Indian market. For plumbing and water supply components, having the ISI mark boosts customer confidence and makes the product more competitive. In infrastructure projects and public water supply systems, ISI mark certification is often a prerequisite, making it a valuable asset for manufacturers aiming for wider acceptance.

Indian Standard IS 7834

(Part 1)

The standard in focus is Injection

Moulded PVC Socket Fittings with Solvent Cement Joints for Water Supplies: Part

1 – General Requirements. This Indian Standard IS 7834 (Part 1) for Injection

Moulded PVC Socket Fittings with Solvent Cement Joints for Water Supplies

provides specifications for design, dimensions, material quality, pressure

rating, and performance testing of the fittings.

This part of the standard applies to injection moulded PVC socket fittings, fittings meant for solvent cement joints, products intended for water supply systems under pressure, and fittings suitable for cold water applications. It ensures that these components can sustain water pressure, resist corrosion, and perform effectively under various environmental conditions.

Why is BIS Certification

Important?

The Bureau of Indian Standards (BIS)

is responsible for maintaining the quality and safety of products through

certification schemes in India. When it comes to water supply fittings, BIS

certification is crucial for the following reasons:

Process of BIS

Certification for Injection Moulded PVC Socket Fittings

Obtaining BIS certification for

Injection Moulded PVC Socket Fittings involves the following steps:

- Application

Submission: Submit the completed application

form with necessary documentation to BIS.

- Document Review: BIS evaluates the submitted documents to verify accuracy and

completeness.

- Factory Inspection: BIS officials conduct on-site inspections to assess

manufacturing processes and quality control systems.

- Sample Testing: Product samples are collected and tested at BIS-approved

laboratories to verify compliance with Indian standards.

- Certification Grant: Upon successful inspection and testing, the BIS issues the certification, allowing the use of the ISI Mark.

Documents Required for BIS Certification

To apply for ISI

Certification for Injection Moulded PVC Socket Fittings, manufacturers must

provide the following documents:

● Completed application form

● Detailed manufacturing process

information

● Quality control plans and test

reports

● Factory layout and equipment

details

● Product specifications and

technical details

● Business registration proof

● Declaration of conformity to

Indian standards

Additional documentation may be required based on product specifications and environmental regulations.

BIS ISI Mark Certification Costing And Timeline

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Conclusion

In a market where quality and

compliance are non-negotiable, obtaining BIS certification for Injection

Moulded PVC Socket Fittings with Solvent Cement Joints for Water Supplies is

not just a regulatory step—it’s a strategic move.

By aligning your product with the

Indian standard IS 7834 (Part 1) for Injection Moulded PVC Socket Fittings with

Solvent Cement Joints for Water Supplies, and ensuring it carries the trusted

ISI mark, you signal quality, safety, and compliance. Looking to get your

product certified? Our expert consultants can guide you through the complete

BIS certification process, right from documentation to factory audit support.

Let us help you earn that ISI mark with ease.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

🕒 BIS Certification No Longer Mandatory for 14 Chemical & Polymer Categories

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile