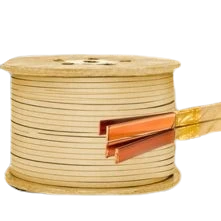

BIS Certification for Paper Covered Copper Conductors IS 7404 (Part 1): 1991

In the world of power generation and

electrical transmission, Paper Covered Copper Conductors (PCC) play a vital

role, especially in the winding of power and distribution transformers. These

conductors are known for their excellent thermal stability, dielectric

strength, and mechanical properties, which make them highly reliable for

critical applications.

To ensure the safety, reliability, and performance of PCCs used across industries, the Bureau of Indian Standards (BIS) has introduced the standard IS 7404 (Part 1): 1991. BIS certification under this standard ensures that the product meets all technical and safety requirements and is approved for use in the Indian market.

What Are Paper Covered

Copper Conductors?

Paper Covered Copper Conductors are

copper wires (round or rectangular) that are insulated using layers of

specially treated paper. The paper serves as an electrical insulator and

protects the conductor from short-circuits, overheating, and breakdown in

high-voltage environments.

About IS 7404 (Part 1):

1991 – BIS Standard for PCC

The Indian Standard IS 7404 (Part 1):

1991 pertains specifically to paper-covered round copper conductors. It lays down

the specifications, construction requirements, dimensions, and testing

procedures for ensuring uniformity and safety in these conductors.

This standard is applicable to

manufacturers of PCC used in electrical equipment such as:

Why BIS Certification Is

Important for PCC

Obtaining a BIS Certification (ISI Mark) is essential for the following

reasons:

● Safety Assurance: Ensures the product

can withstand electrical, thermal, and mechanical stresses.

●Regulatory Compliance: Required to

legally sell the product in the Indian market under the BIS Conformity Assessment Scheme.

● Industrial Credibility: Builds

confidence among transformer manufacturers and power companies that the conductor

meets national standards.

● Market Access: Makes participation in

public tenders and government procurement possible.

● Avoid Penalties: Non-compliance can lead to rejection of shipments or cancellation of contracts.

Key Requirements as per IS

7404 (Part 1):1991

To comply with

the standard and obtain BIS certification, the following parameters must be

met:

●Conductor Material: The conductor must

be made of either annealed or hard-drawn copper, in accordance with IS 191:

2007 (or the latest version). It should be free from impurities and must be

mechanically sound.

● Insulating Paper: The insulating paper

must have high dielectric strength and be properly wrapped. The paper layers

should be free of tears, creases, or overlaps. Acceptable types of paper may

include kraft paper, crepe paper, or other treated varieties.

●Conductor Size and Tolerance: Round conductors must conform to the diameters specified in the standard tables. The dimensional tolerances should be within the limits prescribed in IS 7404.

Testing Parameters for BIS

Certification

The following tests must be conducted

on samples of the paper-covered copper conductor:

● Conductor Conditioning

● Measurement of Wire Diameter

● Width and Thickness of Paper

● Conductor Resistance Test

● Overall Diameter & Increase

in Diameter

● Elongation Test

Process to Obtain BIS Certification for PCC

The certification process involves the

following steps:

●Application Submission: Apply to BIS

through the online portal (ManakOnline). Include product specifications,

manufacturing details, and relevant test reports.

●Factory Inspection: BIS officials will

inspect your manufacturing facilities, production controls, and internal

testing capabilities.

●Sample Testing: Random samples of the

product will be collected and tested in BIS-recognized laboratories.

● Evaluation and Grant of License: If your

products comply with the required standards, BIS will grant a license

permitting the use of the ISI mark on certified products.

●Post-Certification Surveillance: The BIS

will conduct regular audits and sample checks to ensure ongoing compliance.

To Know The Process in Detail, Please Visit:

Under BIS Registration Products ISI and CRS

Documents Required for BIS Certification

To apply for BIS certification, manufacturers need to submit the following documents:

● Application form

● Manufacturing process details

● Quality control plan

● Test reports from BIS-approved laboratories

● Factory layout and equipment details

● Proof of business registration

● Product specifications and technical details

● Declaration of conformity to Indian standards

Additionally, manufacturers may be required to provide proof of compliance with environmental and safety regulations, depending on the specific type of product being certified.

BIS ISI Mark Certification Costing And Timeline

Marking & Packing Guidelines

As per BIS regulations, the following

information must be marked on each spool

or coil of the conductor:

● ISI Mark, if certified

Why Choose EVTL India?

At EVTL India, we specialize in guiding manufacturers through the complete

BIS certification process—from documentation and sample testing to audit

preparation and license acquisition. If you manufacture Paper Covered Copper

Conductors, securing BIS certification is essential for legal compliance,

market trust, and competitive advantage.

Free Call Back

Latest News & Update

📅 BIS Critical Component List (CCL) Updates for Solar PV Modules

🕒 BIS Fee Concessions for MSMEs and Startups | EVTL India

📅 Guidelines for Implementation of Essential Requirements for Security of CCTV

🕒 Omnibus Technical Regulation (OTR) Amendment Order, 2025

🕒 Extension of Timeline for Filing Annual Returns by Battery Producers

📅 Extension of Timeline for Filing Quarterly and Annual Returns for E-Waste

🕒 Extension of Concurrent Running Period for IS 302-1: 2008 and IS 302 (Part 1): 2024

🕒 BIS Guidelines for Grant of Licence (GoL) | EVTL India

📅 CPCB Guidance on filing of Application, Fees and more

🕒 CPCB Notification on Labelling of Plastic Packaging

📅 Mandatory Compliance for Input Materials of Steel and Steel Products for Imports

🕒 BIS Guidelines for Scheme-X Certification for OTR-Regulated Products

📅 BIS Upgrades Product Certification License Numbers to 10-Digit Series

Why Choose EVTL INDIA

Expertise in Indian Regulatory Standards

End-to-End Support

Trusted by Top Indian & Global Brands

Fast Processing & Transparent Pricing

Strong Liaison with Indian Authorities

Company Profile